SAG Commercial Vehicle Company won the "National Machinery Industry Quality Award" for 2021-2022.

Release time:

2022-12-07

Source:

The National Machinery Industry Quality Award is the highest award for quality in the machinery industry approved by the State Council of China. It is organized by China Association for Quality Management in Machinery Industry and is assessed and rewarded in accordance with the Performance Excellence Evaluation Guidelines. The award is selected once a year. It is the highest honour in terms of quality granted to machinery industry enterprises that have implemented performance excellence management in China and have made remarkable achievements in terms of quality, economic and social responsibility.

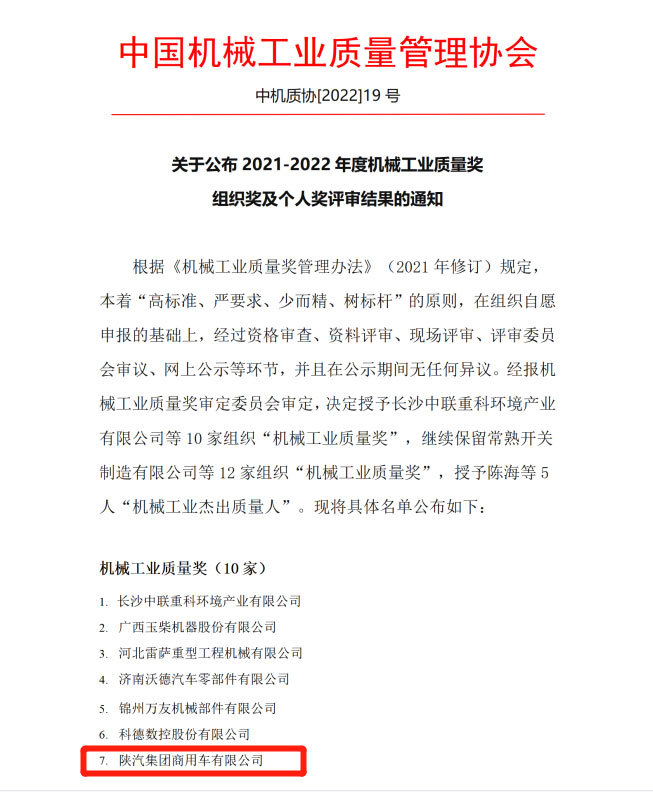

Recently, SAG Commercial Vehicle Company was awarded the National Machinery Industry Quality Award for the year 2021-2022 by the China Association for Quality Management in the Machinery Industry, which released the evaluation results of the Organisation Award and Individual Award of the Machinery Industry Quality Award for the year 2021-2022.

In recent years, the company has kept in mind the requirements of General Secretary Xi Jinping's "Four New" instructions and followed the strategy of accelerating the construction of an powerful nation of automobile . The Company comprehensively applies the performance excellence model and adopts the advanced method of ‘Six Sigma’ to continuously improve product research and development, value creation, quality management system, and human resources construction in seven aspects: leadership, strategy, buyer's market, resources, process management, measurement, analysis, and improvement, as well as business results. The comprehensive competitiveness of the Company is continuously enhanced.

Focusing on the Frontier of Science and Technology & Devoting to Technological Innovation

The company joins hands with Cummins, Yuchai, Fast, Hande Axle and other international famous enterprises, and relies on the strong R&D strength of the national technology centre to build Z3 heavy duty trucks and E3, 6, 9, medium and light duty trucks which have passed the international standard stereotyping test.

The company actively adopts GB17625 (EQV 70/30/EEC), and benchmarks many international advanced standards such as ISO, DIN, SAE, etc., and transforms them into company standards.

Among them: Q/SQ 102027-2015 automotive headlight product standards, exceeding the requirements of similar international standards.

The company participated in the preparation of GB/T 24545-2009 "Vehicle Speed Limit System Technical Requirements" and many other national and industry standards; has "CAN bus intelligent control system in commercial vehicles" and other 26 core technologies, which strongly support the development of technology and industry.

Focus on Innovation to Create High-quality Products

The company makes full use of ISO9001 and IATF16949 standard requirements and process methods to strengthen the quality and safety risk management in new product design and R&D stage, paid close attention to the implementation of the processes of product development project planning, product design, trial testing and production preparation, and strengthened the design of product compliance and consistency, to prevent the occurrence of quality problems at the source. The quality and safety of the production process is constantly and intelligently strengthened. The modular assembly level of the production line has been enhanced, and the ability of the process to safeguard the manufacturing process has been strengthened. The company takes "three presses, three inspections and three no's" as the principle to promote the consistency of assembly and improve the quality of details; establishes the manufacturing process control group and improvement group under the theme of "focusing on process quality, exploring frontline problems, taking the initiative to solve problems and attaching importance to quality training", and Establish a mechanism to quickly solve quality problems.

Focusing on customer needs & Building a synergistic system

In accordance with the "1+2" model layout (each sub-category has one internationally renowned or domestic supplier and 1-2 competitive suppliers), the company has built a collaborative, platform-type, value-type, co-ordination-type, hierarchical supply chain management system.

Focusing on the user, the joint service provider comprehensively improves service timeliness. 7*24 hours, 24 hours a day, accepting users' calls for consultation, repair, complaints, suggestions, and feedback, etc., and carrying out the whole process of control for the timeliness after the user's report for repair to ensure the vehicle's proper operation.

Focusing on culture & Building a talent team

The company promotes the concept of "123456" of Shaanxi Automobile Holding as a guide and integrates the concept of "virtue" culture into all aspects of business management, to unify the mindset and build consensus. Strengthen the learning of corporate culture for all staff. Leaders and cadres personally speak and take the lead in learning. Our training covers all employees, which will help transform the corporate culture into the emotional identity and behavioural habits of all employees. The company uses micro letter public platform, newspapers, bulletin boards and other media to widely disseminate the connotation of de culture system, promote socialist core values, and integrate the promotion of enterprise culture with the deeds of advanced people, production and operation enhancement, and the overall quality of the staff in various aspects.

The company actively establishes co-operation with Xidian University, Chang'an University, Shaanxi Automobile Technical School, and other institutions, in order to improve the education and skill level of employees. At the same time, the internal trainer team is established. Multi-frequency specialised training is carried out. Through the network training platforms such as Talent Cultivation Sharing Platform and Employee Growth Support System, as well as the offline learning areas such as Reading Room of Staff House, the company provides the place and tool support services for the employees, thought of building a knowledge-based, skill-based, and innovative workforce.

Key words:

remarkable,achievements

Related News